Tech

Flame Scans: Enhancing Safety and Efficiency in Industrial Settings

Published

2 years agoon

By

Jack

Flame scans play a crucial role in ensuring the safety and efficiency of various industrial processes. These advanced monitoring systems provide real-time analysis of flame characteristics, allowing for early detection of potential issues and optimization of combustion processes. In this article, we will explore the concept of flame scans, their applications, benefits, implementation, maintenance best practices, and future trends in the field.

Table of Contents

Toggle1. Introduction

1.1 What are Flame Scans?

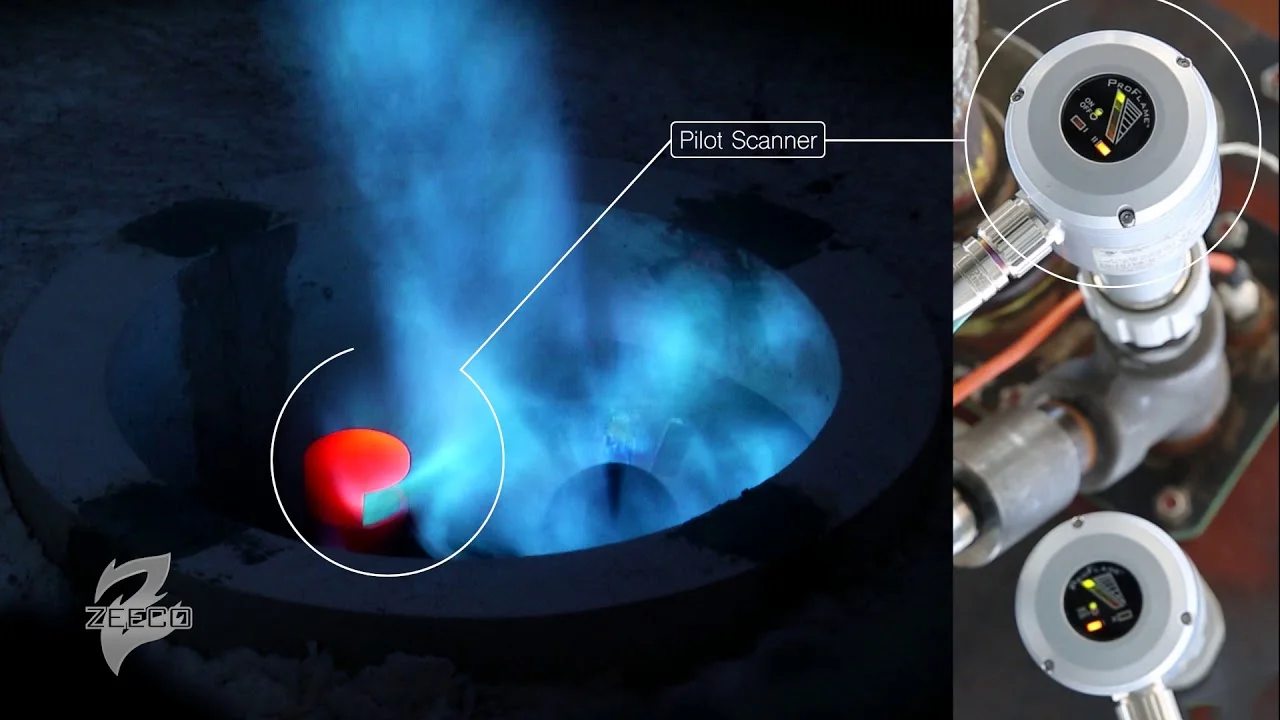

Flame scans, also known as flame detectors or flame sensors, are specialized devices used to monitor and analyze flames in industrial settings. They utilize advanced technologies to detect and measure flame parameters such as intensity, color, flicker, and stability. By continuously monitoring these characteristics, flame scans help ensure the safe operation of various combustion processes.

2. Understanding Flame Scans

2.1 The Importance of Flame Scans in Industrial Settings

Flame scans play a critical role in maintaining safety standards within industrial environments. They provide early detection of flame abnormalities, such as flameouts or unstable combustion, which can lead to hazardous situations, equipment damage, or production inefficiencies. By promptly alerting operators to potential issues, flame scans enable timely intervention and preventive measures.

2.2 How Flame Scans Work

Flame scans utilize various detection methods, including ultraviolet (UV), infrared (IR), and combined UV/IR sensors. UV sensors are sensitive to ultraviolet light emitted by flames, while IR sensors detect the infrared radiation produced by combustion. Combined UV/IR sensors offer increased reliability by utilizing both detection methods.

When a flame is present, the sensors detect the emitted light or radiation and transmit signals to a control system. This system analyzes the signals to determine flame characteristics and triggers appropriate responses or alarms in case of anomalies.

3. Applications of Flame Scans

3.1 Flame Scans in Oil and Gas Industry

In the oil and gas industry, flame scans are extensively employed in various applications, including flare stacks, refineries, and storage facilities. They ensure the continuous monitoring of combustion processes, preventing accidents, and improving operational efficiency. Flame scans enable early detection of flare stack flameouts, which can lead to dangerous releases of flammable gases and subsequent hazards.

3.2 Flame Scans in Power Plants

Power plants heavily rely on combustion processes to generate electricity. Flame scans are used to monitor flames in boilers, furnaces, and turbines, ensuring efficient and safe power generation. By analyzing flame characteristics, these systems optimize combustion parameters, minimizing pollutant emissions and improving overall plant performance.

3.3 Flame Scans in Chemical Manufacturing

Flame scans find valuable applications in chemical manufacturing processes, where controlled combustion is crucial. They help prevent unwanted ignition sources, detect flame instabilities, and optimize the efficiency of burners and reactors. Flame scans contribute to safer production environments and higher yields of quality chemical products.

4. Benefits of Flame Scans

4.1 Enhancing Safety Measures

By providing real-time monitoring and early detection of flame abnormalities, flame scans significantly enhance safety measures in industrial settings. They minimize the risks of fires, explosions, and equipment damage, protecting personnel and assets.

4.2 Optimizing Combustion Efficiency

Flame scans enable the optimization of combustion processes by analyzing flame characteristics and providing valuable insights for adjustments. By maintaining stable and efficient combustion, these systems improve energy efficiency, reduce fuel consumption, and lower operational costs.

4.3 Preventing Unwanted Emissions

Efficient combustion facilitated by flame scans results in reduced emissions of pollutants, contributing to environmental sustainability. By closely monitoring flame parameters, these systems help ensure compliance with regulatory standards and minimize the impact on the environment.

5. Implementing Flame Scans

5.1 Choosing the Right Flame Scan System

Selecting the appropriate flame scan system requires considering factors such as the application, operating conditions, detection range, and communication capabilities. It’s crucial to consult with experts and choose a system that meets the specific requirements of the industrial process.

5.2 Installation and Calibration Process

Proper installation and calibration of flame scans are vital for accurate and reliable operation. Following manufacturer guidelines, trained professionals should install and align the sensors correctly. Regular calibration and testing should be performed to ensure optimal performance and early detection of anomalies.

6. Best Practices for Flame Scan Maintenance

6.1 Regular Inspections and Cleaning

Routine inspections and cleaning of flame scan systems are essential to remove dust, debris, or other contaminants that may hinder their performance. Regular maintenance procedures should include thorough checks, sensor cleaning, and verification of connections to ensure uninterrupted functionality.

6.2 Monitoring and Troubleshooting

Continuous monitoring of flame scan data allows for the timely detection of potential issues. Operators should be trained to interpret the system’s output and respond to alarms promptly. In case of malfunctions or false alarms, troubleshooting should be performed to identify and rectify the underlying causes.

7. Future Trends in Flame Scan Technology

7.1 Integration with Artificial Intelligence

The integration of flame scans with artificial intelligence (AI) technology holds great potential for enhancing their capabilities. AI algorithms can analyze complex flame data patterns and identify anomalies or predict potential issues, further improving safety measures and combustion optimization.

7.2 Advances in Remote Monitoring

Advancements in connectivity and remote monitoring systems enable real-time monitoring of flame scans from centralized control rooms. This allows for more efficient monitoring across multiple locations and facilitates proactive maintenance and troubleshooting.

8. Conclusion

Flame scans play a vital role in ensuring the safety, efficiency, and environmental sustainability of various industrial processes. By continuously monitoring flame characteristics, these systems enable early detection of anomalies, optimization of combustion processes, and prevention of unwanted emissions. Implementing flame scans, following best practices for maintenance, and embracing future technological advancements can greatly benefit industrial operations.

FAQs

9.1 What is the lifespan of a flame scan system?

The lifespan of a flame scan system can vary depending on several factors, including the quality of the system, the operating conditions, and the maintenance practices. Generally, well-maintained flame scan systems can have a lifespan of 5 to 10 years or more.

9.2 Can flame scans detect multiple fuel types?

Yes, flame scans can detect and monitor flames resulting from various fuel types, including natural gas, oil, coal, and biomass. They are designed to analyze the characteristics of the flame itself, regardless of the specific fuel being burned.

9.3 Are flame scans suitable for outdoor installations?

Yes, flame scans can be suitable for outdoor installations. However, when installing flame scan systems outdoors, considerations must be made to protect the sensors from environmental factors such as weather conditions, dust, and debris. Proper enclosures and protective measures should be employed to ensure optimal performance.

9.4 Can flame scans reduce operational costs?

Yes, flame scans can contribute to the reduction of operational costs. By optimizing combustion processes and ensuring efficient fuel utilization, these systems can help minimize fuel consumption, improve energy efficiency, and reduce operational expenses in industrial settings.

9.5 How often should flame scans be recalibrated?

Flame scans should be recalibrated at regular intervals to maintain accurate and reliable performance. The recommended frequency of recalibration can vary depending on the specific system and manufacturer guidelines. Typically, recalibration is recommended annually or as per the manufacturer’s specifications.

Author